Yes if parts are flat and can use tools to remove support easilyĮxamples of the different SMART SUPPORT Styles:ģD Sprint ® is programmed by default to draw the supports twice for the Accura AMX Durable Natural material to increase the stiffness of the structure. Double-drawing the supports adds to the total print time by doubling the support drawing time, but it is required to properly cure the support structures, print taller structures and longer prints (24 hours or more). However, this method is faster and far more effective than increasing the Border Overcure amount for a single draw of the support vectors. The Border Overcure value is how much additional cure depth is added past the current layer. Less Border Overcure means less total cure depth and thus allows for faster draw speeds. These parameters have been optimized and set as default to ensure build success. Not Recommended, supports will be very difficult to removeįlat oriented parts where supports can be easily accessed with spatulas or cutting tools. Use the table below to select the style in the SMART SUPPORT and Support Build Style that best works for the parts being built: Support Style: The different Support Build styles can be selected from the Build Style drop down menu: To access the different SMART SUPPORT styles, they can be selected from the drop-down menu: There are several options available to the user for support generation.

To properly setup and support the parts, it is recommended to use the SMART SUPPORT feature in 3D Sprint for generation of support structures.

#QUICKCAST SLA FULL#

Whether you just need QuickCast patterns printed or a full turnkey investment casting solutions, LI ProParts can supply you needs.Properly supported parts are critical to final part accuracy, and print reliability.

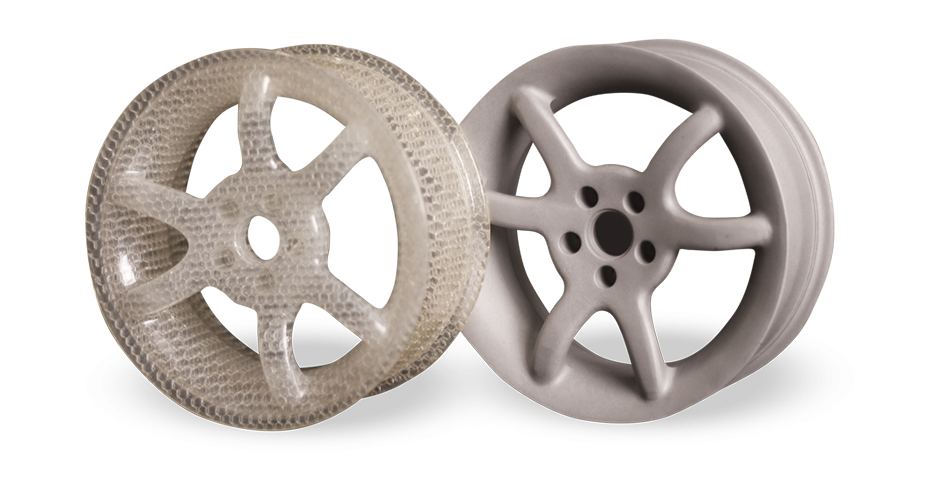

QuickCast patterns provide several advantages compared to other direct patterns including low moisture absorption, high finish, dimensional stability and capabilities of producing large assemblies. The QuickCast build style consists of a hollow stereolithography pattern with an internal hexagonal support structure that adds strength to the pattern, allows for easy drainage, and facilitates collapse of the pattern during thermal expansion to help avoid cracking the shell. QuickCast patterns are a hollow SLA build style with hexagonal support structures. QuickCast patterns were the first direct pattern. Double-drawing the supports adds to the total print time by doubling the support drawing time, but it is required to properly cure the support structures, print taller structures and longer prints (24 hours or more). QuickCast replaces the time consuming process of creating tooling to produce wax patterns, allowing the review of metal designs in days instead of months. QuickCast is an SLA build style and was created to meet the needs of the investment casting industry. 3D Sprint is programmed by default to draw the supports twice for the Accura AMX Durable Natural material to increase the stiffness of the structure. QuickCast patterns for investment casting have had the most profound effect on this industry. As for the issue of ceramic shell cracking, SLA successfully uses QuickCast technology that creates a semi-hollow inner structure of pattern walls as shown.

QuickCast patterns were the first direct pattern (patterns created via a 3D printing QuickCast is an SLA build style and was created to meet the needs of the Investment Casting industry. The bottom line is, many parts are perfect candidates for investment casting. 005″ per inch held, and expenses and time involving machining and finishing reduced or eliminated. Parts can be reduced in weight, tolerances of ±. The lost-wax process has proven to be a cost effective way to produce prototypes, short runs or full production metal components. Investment casting has, without a doubt, earned its place in manufacturing.

0 kommentar(er)

0 kommentar(er)